Under the brand name reSound OM PolyOne has introduced TPE formulations for overmoulding processes. The grades utilise between 40 and 50 % bio-renewable content derived from sugarcane, and offer hardness levels and performance comparable to standard TPEs, PolyOne said.

“OEMs want to incorporate environmentally responsible materials in their designs, especially those who manufacture consumer products, yet they also need to meet functional requirements,” said Jim Mattey, global marketing director, Specialty Engineered Materials at PolyOne. “New reSound OM grades address both goals by leveraging a significant amount of renewable content without compromising the material’s properties.”

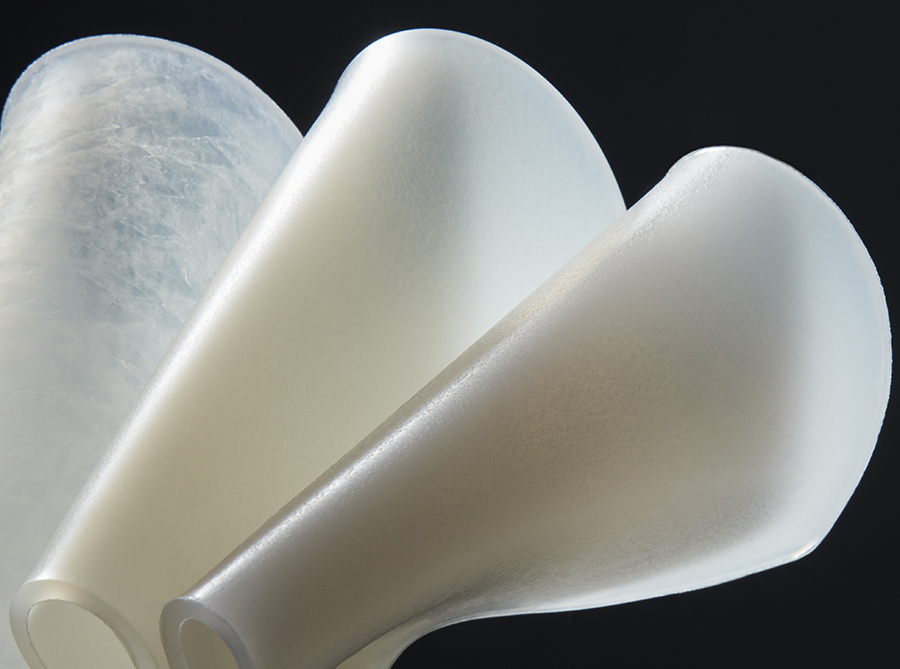

Commercially available in all regions, the product portfolio consists of four overmoulding grades compatible with rigid polypropylene and one suited for overmoulding onto ABS. All grades are formulated for durability, delivering property retention and UV resistance comparable to traditional TPE. In addition, the new grades feature easy colourability, a major requirement for applications such as cosmetics packaging, personal care products, and consumer electronics. With an opaque natural color, all reSound OM materials can either use traditional TPE colourants or be paired with sustainable colorants from PolyOne. Further supporting sustainability, when manufacturing with reSound OM, production scrap material can be reused.

“Innovation is in our DNA, and we are committed to helping our customers achieve their sustainability goals with products such as reSound OM,“ added Walter Ripple, vice president, Sustainability at PolyOne. “Our investments in R&D, resulting sustainable solutions portfolio, and support for solutions to the plastic waste problem are outward signs of that commitment.”