Hexpol TPE will be showcasing its portfolio of thermoplastic elastomers optimised for automotive interior applications at Fakuma 2018. Highlights are new technologies to address emerging automotive trends, particularly with regards to sustainability and vehicle interior air-quality.

According to the company, in a move to improve passenger comfort, legislation regarding odour, fogging and VOC/FOG emissions has increased in recent years and OEMs such as Daimler and VW have also tightened limits. Several countries regulate the maximum allowed concentration of substances which can be hazardous to health, such as formaldehyde, benzene and nitrosamines (for example the Chinese standard GB/T27630).

At the trade show, Hexpol TPE will present Dryflex Interior, a series of TPE compounds which are optimised for low emissions. The new TPEs are said to offer on average a 75 % emission reduction compared to other TPEs for interior applications on the market. They display low odour with results 2.0 to 3.0 in standards such as VDA 270. According to gravimetric fogging standard ISO 6452, they achieve condensate < 1.0 mg, VOC results from 60 – 120 µg/g and Fog from 200 – 600 µg/g.

Furthermore, Dryflex Interior TPEs have passed interior tests for lightfastness, flammability and mechanical performance. Currently available in hardnesses between 25 and 85 Shore A, they offer good processing and the possibility of finely structured surfaces or complex geometry in the part design, said Hexpol TPE. They are available in customer specific colours as well as black and natural.

Philippe Julien Labruyère, sales director Hexpol TPE, commented: “We’re seeing year-on-year growth in sales to automotive, in particular for interior applications where TPEs are widely used to add design features or functional performance benefits. We believe Dryflex Interior are the best performing TPEs available in the market for VOC and FOG emissions, they allow customers to surpass standards set by OEMs and legislation and prepare for even stricter limits in the future”.

In addition, Hexpol TPE has expanded its Dryflex Green range of bio-based TPE compounds. These TPEs incorporate a high amount of raw materials based on renewable resources such as sugarcane. Depending on the hardness of the TPE, a renewable share of over 90 % is possible. Properties and processability are similar to regular fossil-based TPE compounds, said Hexpol TPE.

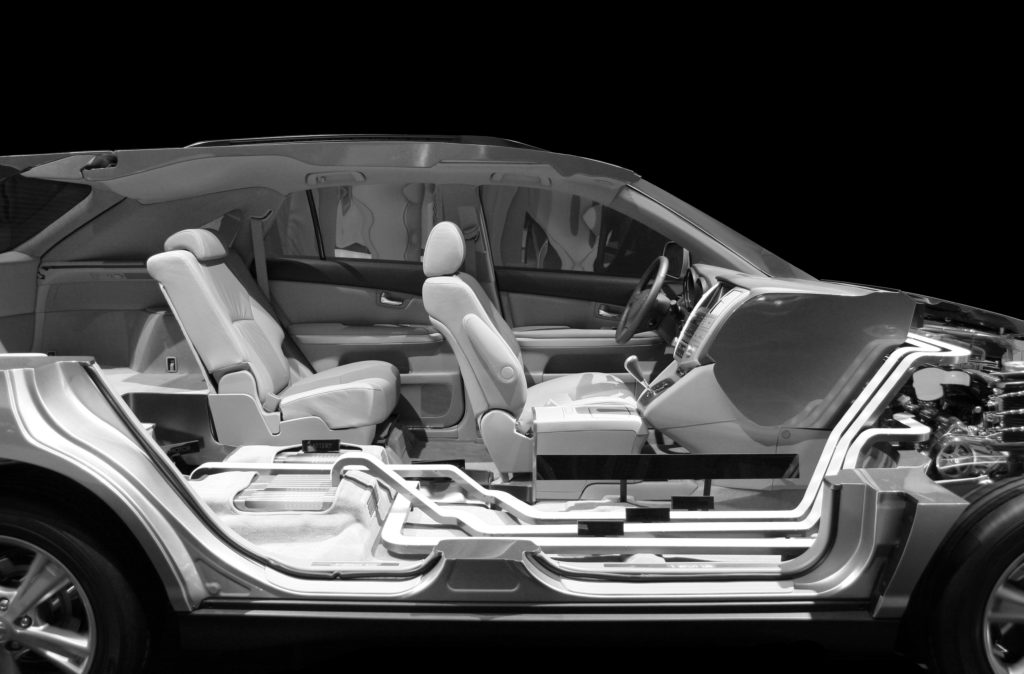

Dryflex Green TPEs with low emission values will be presented at Fakuma. For example, a 65 Shore A compound with a renewable content of 40 % showed a very low amount of VOC (82 µg/g) and Fog (142 µg/g) in the thermodesorption test according to VDA 278. Dryflex TPEs for automotive interiors can be used in applications such as inlay mats in the dashboard, door, middle console or glove box. They are also well suited for thumb wheels, switches, cup holder liners, interior trim, and HVAC components.

Emission values of Dryflex Interior TPE

| Method | Typical OEM requirements | Currently used TPE for automotive interior | Dryflex Interior TPE |

| Gravimetric fogging (ISO 6452) | ≤ 2.0 mg | 1.0 – 2.0 mg | 0.3 – 0.7 mg |

| Thermodesorption (VOC, VDA 278) | ≤ 500 μg/g | 100 – 400 μg/g | 60 – 120 μg/g |

| Thermodesorption (Fog, VDA 278) | ≤ 1,500 μg/g | 2,000 – 3,000 μg/g | 200 – 600 μg/g |

| Odour (VDA 270, B3) | ≤ 3.0 | 3.5 – 4.0 | 2.0 – 3.0 |

| Hexpol TPE at Fakuma 2018 Hall B1, stand B1-1217 |