The current situation caused by the global COVID-19 pandemic demands safe but also sustainable material solutions for medical and healthcare equipment. Elastron has been actively collaborating with customers across the globe to utilise its broad portfolio of thermoplastic elastomer materials for reusable masks and other healthcare products.

The need and demand for facemask equipment continues to rise and Elastron is working in close cooperation with customers in the healthcare market to provide TPE materials that combine durable performance with comfortable ergonomics. One such area is reusable masks, which help reduce the risk and spread of infections by limiting the transmission of infectious agents. They can be reused many times over simply by changing the filter and cleaning and disinfecting the mask components, providing environmental sustainability and effective cost management.

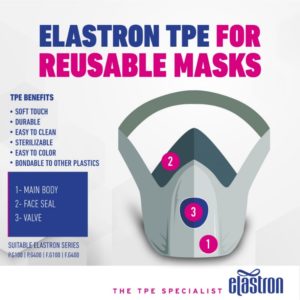

Material selection is critical in the healthcare market and Elastron can provide a broad range of different properties to meet the functional and design requirements associated with the mask body, face seal, valves, and straps for reusable mask applications. The TPEs provide a soft feel and comfortable ergonomics while also meeting durability, cleaning, and sterilisation requirements for repeated use. They are easily colourable and bondable to wide variety of plastics, providing design flexibility and process optimization. Suitable Elastron materials include the P.G100, P.G400, F.G100, and the F.G400 series.

Elastron TPEs for the healthcare industry meet compliance requirements of USP Class VI, ISO 10993-5, EU 10/2011 and FDA.