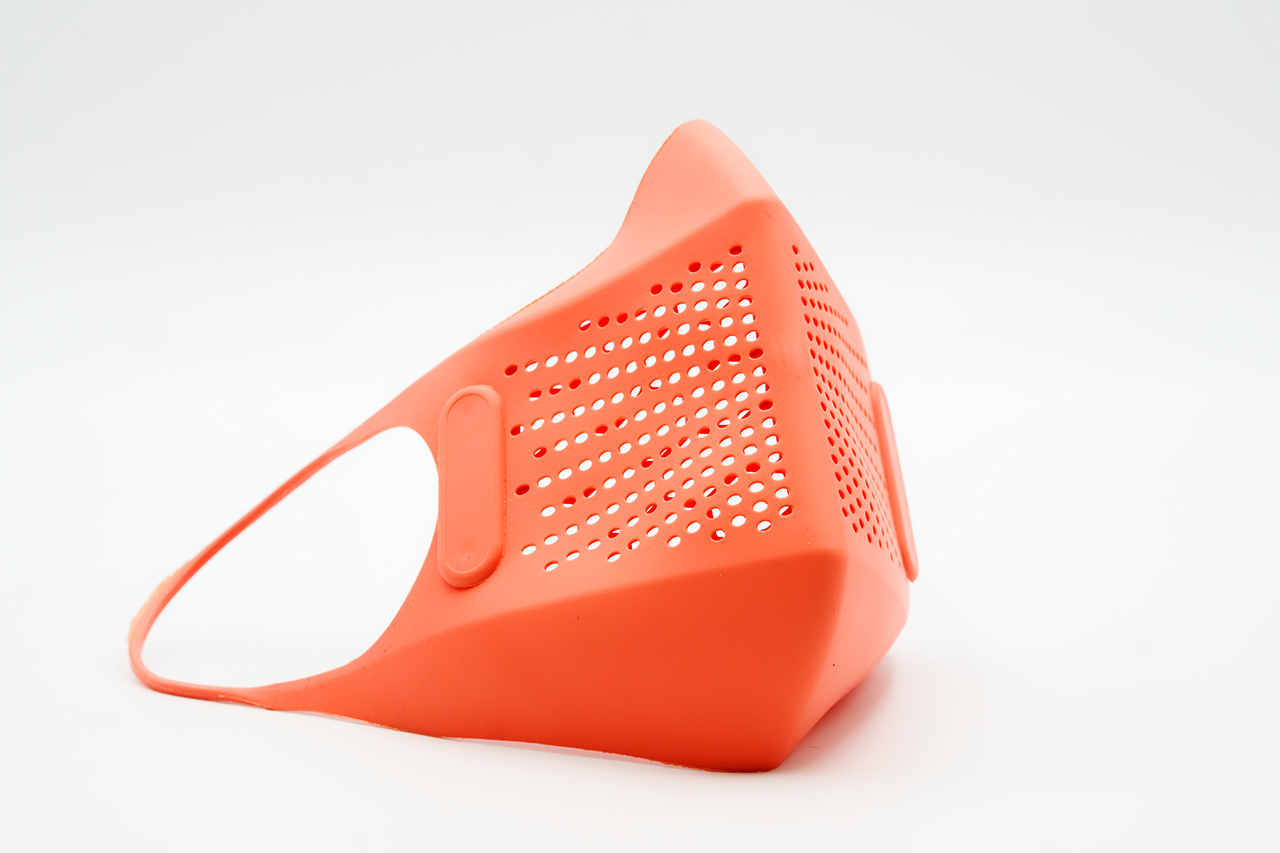

The Italian compounder Marfran teamed up with injection molding machinery supplier Negri Bossi for the production of face masks. Negri Bossi coordinated a pool of companies including Marfran and started in less than five weeks the production of reusable masks, sterilisable with interchangeable filter. The mask is entirely made of TPE. The Marfran.Med compounds were donated for this project by Marfran.

The wide hardness range of the Marfran TPE series allows to create comfortable but at the same time robust, reusable, and durable masks as well as parts for personal protective equipment. The compounds, based on copolymer elastomers with hydrogenated iron blocks, can offer a high level of hygiene, are hypoallergenic, free from latex and other allergenic substances. They are biocompatible, do not contain phthalates or other dangerous substances as demonstrated by the numerous biocompatibility tests conducted according to international standards applied on medical devices. The compounds meet the requirements dictated by ISO 10993 and the American Pharmacopeia USP <88> Class VI. They can be used to produce personal protective masks compliant with European standard EN 149, or a facial protective mask for medical use compliant with European standard EN 14683.

| Hardness range in Shore A | Protective mask facial for medical use | Filter semiforms | |

| Material type | EN 14683 | EN 149 (FFP) | |

| Standard molding | From 30 to 90 | Marfran.Med series ST | Marfran E series G1 |

| High fluidity molding | From 30 to 90 | Marfran.Med series LV | Marfran E series FG1 |

| High temperature: sterilizable | From 30 to 90 | Marfran.Med series M | Marfran E series M1 |

| Transparent | From 30 to 90 | Marfran.Med series TR | Marfran E series KK |

| Overview of Marfran compounds for face masks and personal protection equipment (Source: Marfran) | |||

www.marfran.com

www.negribossi.com

www.bionyca.com

www.eurgomma.it