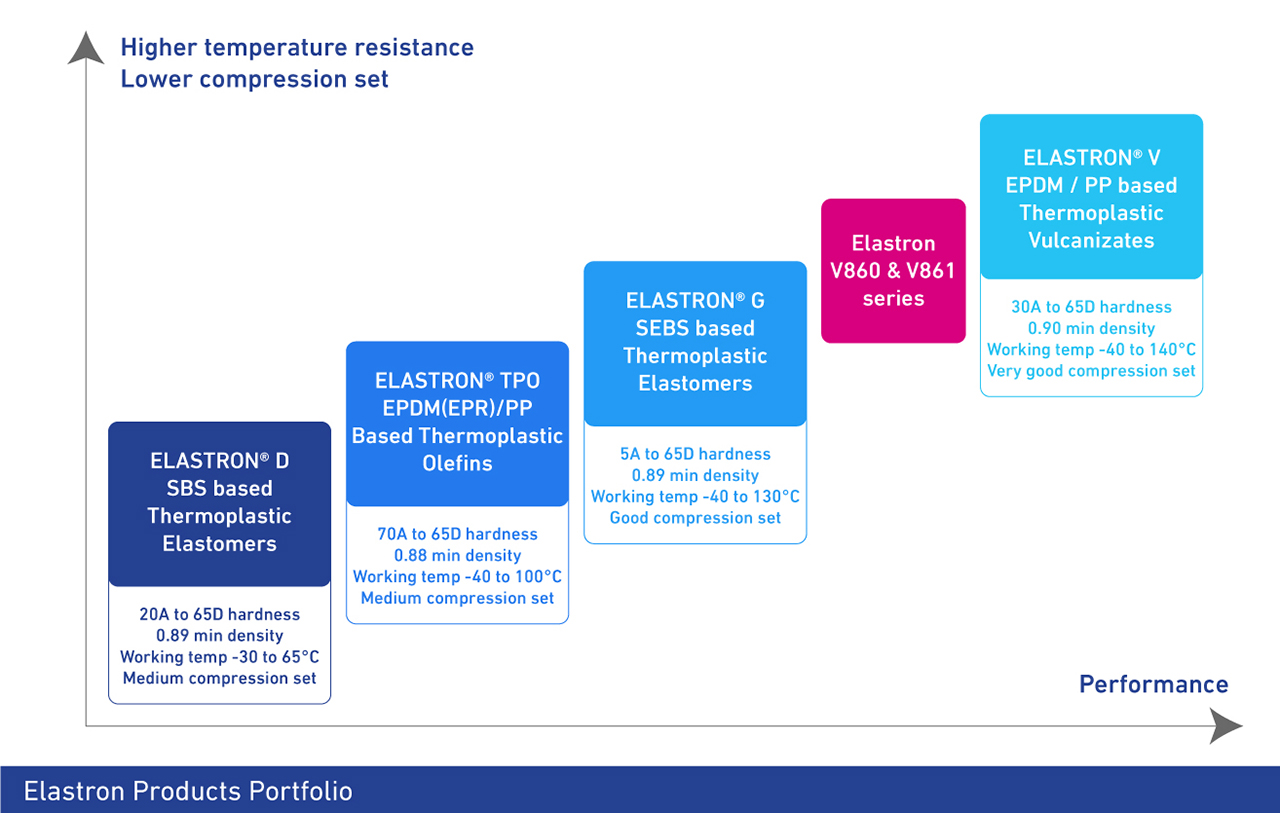

The V860 and V861 series of thermoplastic elastomers have been developed by Elastron to provide an alternative to standard TPVs on the market today. The grades are said to exhibit product performance comparable to standard TPVs and superior to SEBS-based TPEs.

Key features include:

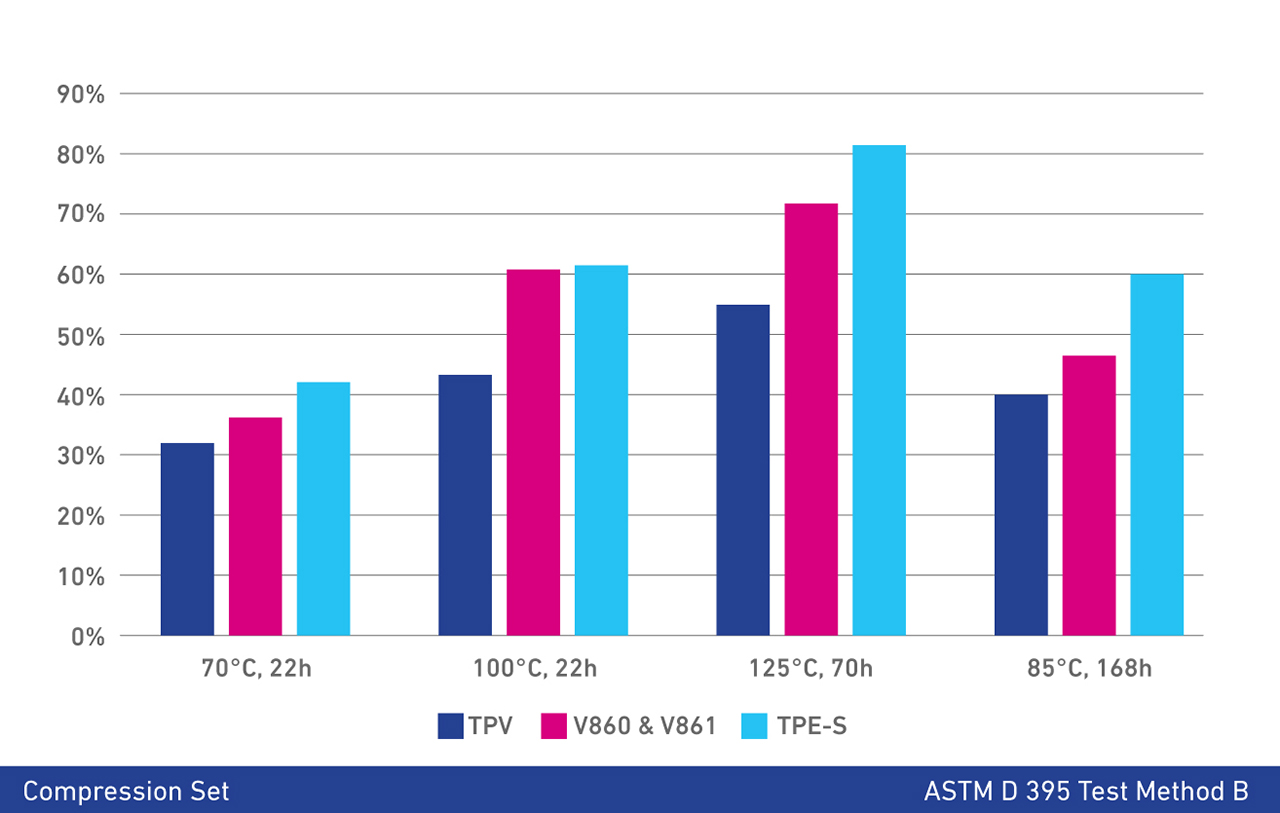

- Very good heat resistance and compression set properties

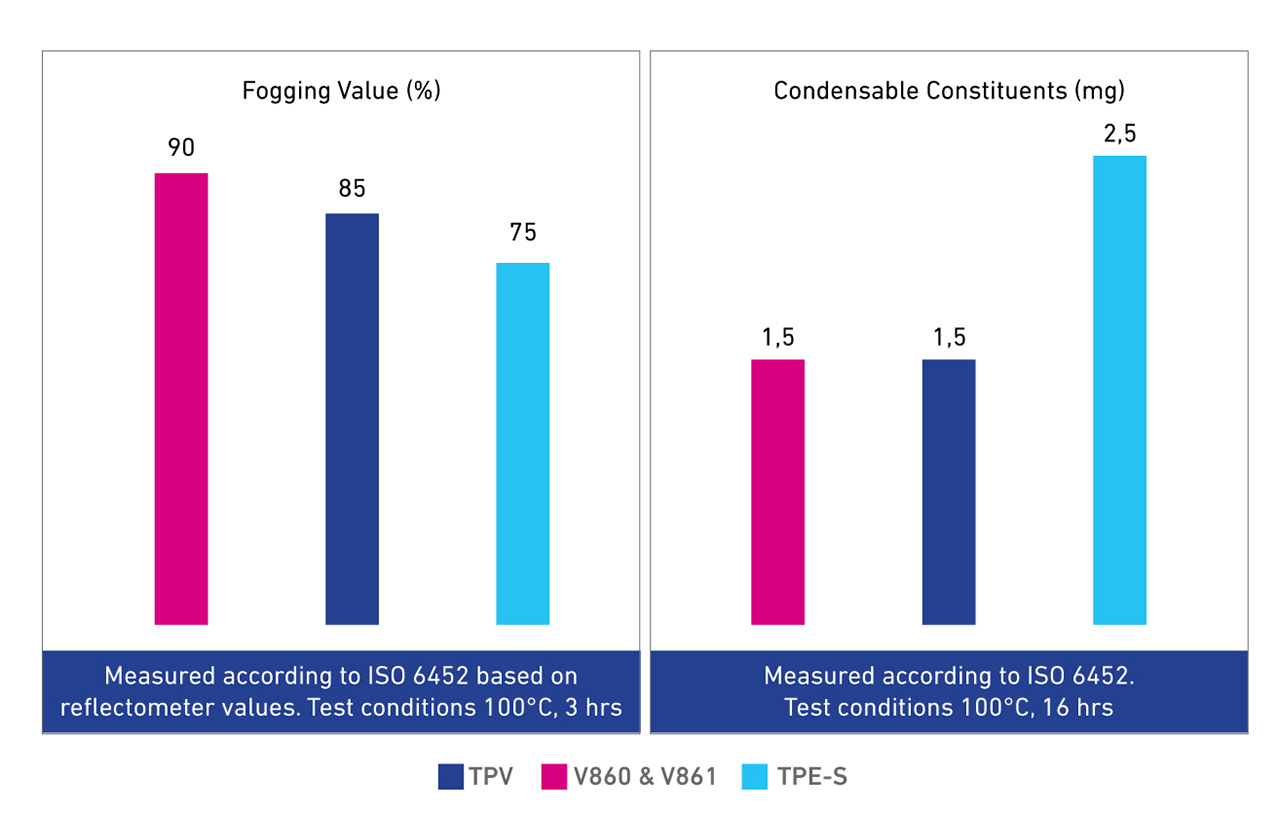

- Low condensable constituents and fogging; suitable for auto interior applications

- Non-hygroscopic, no pre-drying required; no black specks

- Very good processability in both extrusion and injection-molded applications

- Excellent surface aesthetics

The V860 series is designed for injection molding with hardness ranging from 45 Shore A to 75 Shore A and density of ~0.95 g/cm³. The V861 series is well-suited for extrusion or injection molding processes with hardness ranging from 55 Shore A to 80 Shore A and density of ~1.10 g/cm³.