Fröbel together with its partner company Ako has developed a face mask. The parts for the mask are produced at the Fröbel facility using injection moulding technology from Wittmann Battenfeld and a TPE supplied by TPE compounder Allod.

Reusable and comfortable to wear thanks to TPE

Fröbel, a family-owned company in the second and third generation, was founded in 1949. With the production of thermometers, the company entered the plastics processing industry in 1960. Today, it supplies its products to virtually all non-automotive sectors of industry. Its portfolio of goods and services ranges from the development and production of individual parts and complete assemblies to finished products. In some cases, Fröbel even takes care of its customers’ logistics right up to the end customer.

The latest product from Fröbel is reusable community mask, which the company has developed jointly with its partner company Ako. For Tobias Fröbel, the company’s junior managing partner, the main consideration in this project apart from the desire to help with the fight against COVID-19 was the aspect of sustainability. Therefore it was important to him to develop a reusable product with the filter fleece being the only disposable part.

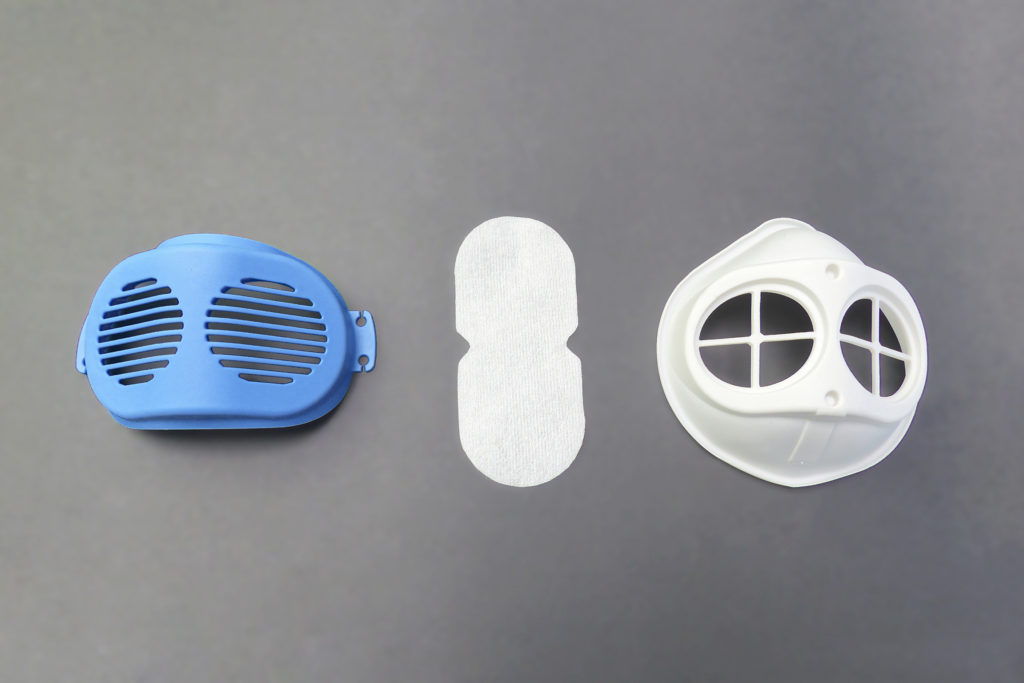

The mask consists of a base with a top piece, on which flexibly adjustable elastic bands are fastened. The base is produced from a supple, elastic grade of TPE, which provides a high degree of protection together with excellent wearing comfort. The TPE is a Allruna TPS compound supplied by compounding specialist Allod. In addition to serving as the fixture for the elastic bands, the top piece holds the disposable PP filter fleeces in place, of which a package of ten is automatically included in the delivery of the mask to the end customer. The masks can be cleaned with standard disinfectants or with hot water. When people put them on or take them off, they do not come into direct contact with the disposable fleece. Basically, the masks can be upgraded with a great variety of filter media. Apart from the high wearing comfort due to the soft, elastic base, customers appreciate the light weight, good speech attributes and high air permeability of the large filter area.

The masks are available in two sizes. In addition to the standard model M, a 20 % smaller S version has been developed, which is intended primarily for women and children. For large-quantity orders, a customised colour choice is also possible. The S model primarily intended for women and children is available with a choice of several different colours as standard.

The masks are manufactured at both Fröbel and Ako and sold worldwide. They are currently distributed exclusively in the B2B sector. A B2C solution with partners is in preparation. Currently 70,000 S model masks and 140,000 M model masks are being produced per week, of which 70,000 are manufactured at Fröbel.

At present, the mask is undergoing a CPA / FFP2 certification process. With this certification, the masks would be officially recognised as Corona virus pandemic respiratory masks.

The injection moulding equipment

Of the 40 injection moulding machines installed at Fröbel, ranging from 150 to 6,000 kN in clamping force, 36 are from Wittmann Battenfeld, among them large machines from the MacroPower series, all-electric machines from the EcoPower series, as well as machines from the servo-hydraulic SmartPower series. The robots, a total of 30, have also come from Wittmann Battenfeld. Moreover, Fröbel operates its own mould making shop.

The production of the mask at Fröbel is carried out with a two-cavity mould on a machine of the servo-electric SmartPower series with 900 kN clamping force, equipped with a Primus 16 robot. Fröbel plans to extend the production capacity in the near future by adding another four two-cavity and four-cavity moulds currently under construction. These moulds will be used on two machines of the all-electric EcoPower series with 1100 kN clamping force and a hydraulic HM 110 model.

With the production of its reusable masks using the machines of the SmartPower and EcoPower series Fröbel also makes another contribution to protecting the environment, since one of these machines’ attributes is high energy efficiency, an aspect of particular importance to both Tobias Fröbel and his father, Joachim Fröbel, who is the company’s CEO. The high process stability and easy operation of the machines, as well as their integrated robot concepts, are also appreciated at Fröbel. Tobias Fröbel comments: “The machines from Wittmann Battenfeld are reliable, energy-efficient and easy to operate. An additional benefit is their compact design, which helps us to make optimal use of the valuable space in our production plant.”

www.froebel-kunststoff.de

www.wittmann-group.com

www.communitymaske-ako.de

www.allod.com