Davis-Standard once again exhibited at MD&M West in Anaheim in February. The company showcased a running TPE tubing line at its stand. The line is capable of processing a variety of flexible tubing materials at speeds up to 300 feet / min (91 mpm).

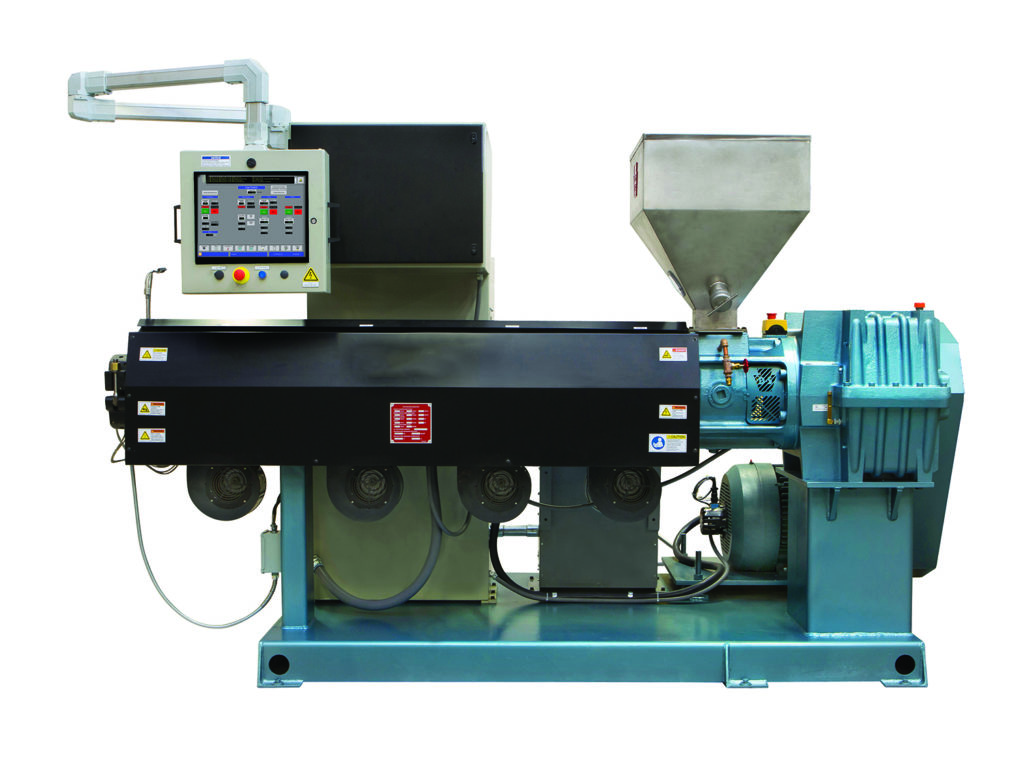

Line components include a 2-inch (50 mm) Super Blue Extruder with e-TPC-II controls, a Guill spiral crosshead die and tooling, a Conair 12-foot multipass vacuum sizing tank, a servo puller and automatic and transfer coiler, and Zumbach OD/ID wall gauge and control system. Davis-Standard has worked with Guill, Conair and Zumbach for many years to supply complete systems solutions to customers. The TPE tubing measured 0.145” OD by 0.0108”ID. The TPE material was supplied by Teknor Apex.

The company said that the DS-eTPC II control has become a popular option for medical tubing processors, adding flexibility to support more applications at an attractive price point. It has a larger 15-inch (380 mm) viewing screen with multi-touch capabilities to enable zoom-in and out, as well as extruder control for up to three extruders with real-time and historical data trending. The DS-eTPC also has integration capabilities for vendor downstream equipment to enable communication and line control from one location. Other benefits include an increase of heat-only zones from four to eight, with an option up to 20; two auxiliary drives; a remote set-point; and speed trim via discrete inputs from gauging equipment.