Teknor Apex offers the Monprene CP-16500 series, designed specifically for dog chew toys. The grades offer an extensive range of performance and aesthetic characteristics, including enhanced bite and tear resistance, and varying gloss levels and opacity. Formulated only with FDA listed ingredients, these TPEs are manufactured under strict quality standards, said the company. The materials meet relevant requirements of European Directives for Food Contact, EU 1935/2004 and PIM10/2011. They do not contain PVC, BPA, Latex, phthalates, or metals and are manufactured in ISO-9001 certified facilities in the USA, Singapore, and Germany to serve local markets. They are suitable for use in pet and children’s toys per regulatory standards CPSIA, EN 71 and ASTM F963.

Unlike rubber used in the manufacture of many chew toys, Monprene TPE is recyclable. Scrap recovered from any step in the manufacturing process can be re-introduced into the process or used in the production nof new parts. Additionally, used chew toys can be recovered, shredded, and recycled into new ones.

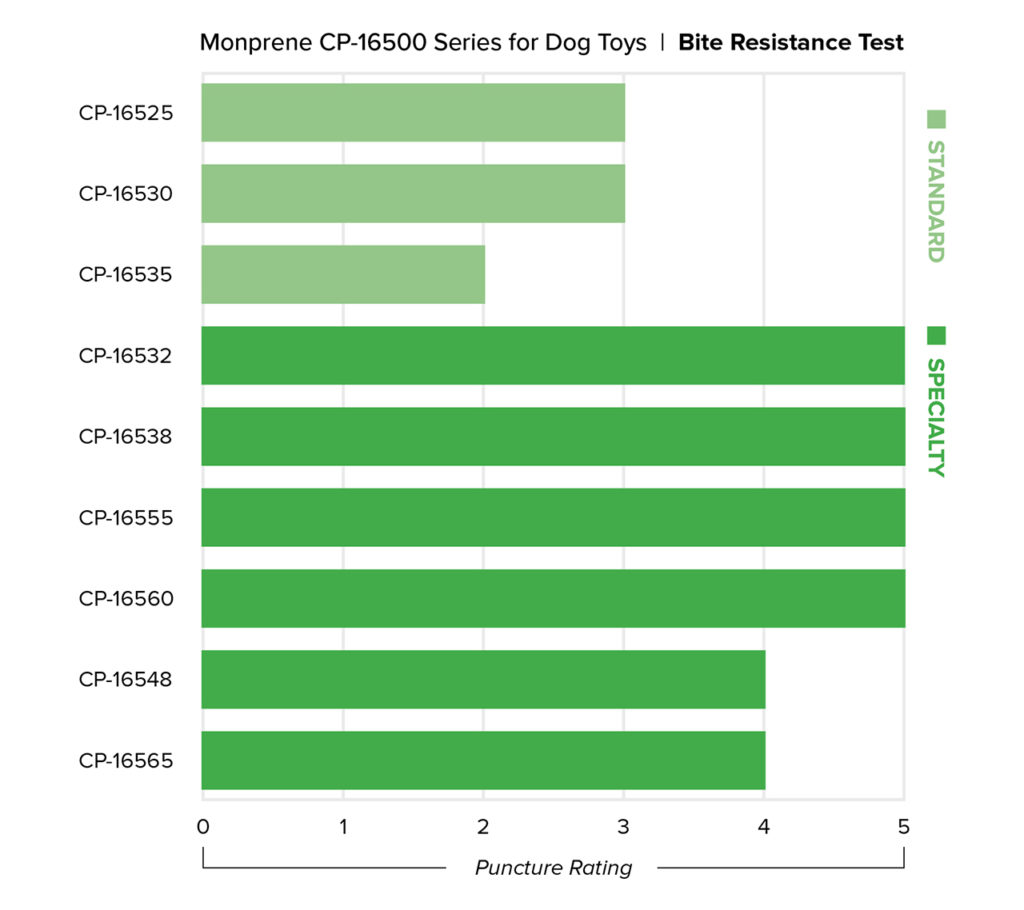

In order to help compare the durability of different materials, Teknor Apex designed a laboratory test to simulate the action of a dog biting a toy. Based on the ASTM test method F1306 for flexible films, the Teknor Apex Bite Resistance test measures the puncture resistance, or the force required to penetrate a material, using an injection molded specimen. A “Puncture Rating” is assigned to each material based on this force, and uses a scale of 1 to 5, with 5 having the greatest resistance. The figure below shows that the MonpreneCP-16500 specialty grades exhibit excellent bite resistance.