With the market launch of its new Aerothan bicycle tube on 8 October 2020, Schwalbe has presented a new generation of bicycle tubes based on BASF’s thermoplastic polyurethane Elastollan. According to the companies, this innovation scores top marks in terms of weight, puncture resistance, handling characteristics, ease of assembly and packing size. Aerothan bicycle tubes are the result of unique developmental work between the producer of bicycle tyres and tubes and BASF’s Performance Material Division.

“In developing Aerothan bicycle tubes, we were breaking new ground right from the start,” said Felix Schäfermeier, Product Manager at Schwalbe. “The combined ingenuity and developmental work of BASF and Schwalbe has resulted in a high-end alternative to conventional bicycle tubes.”

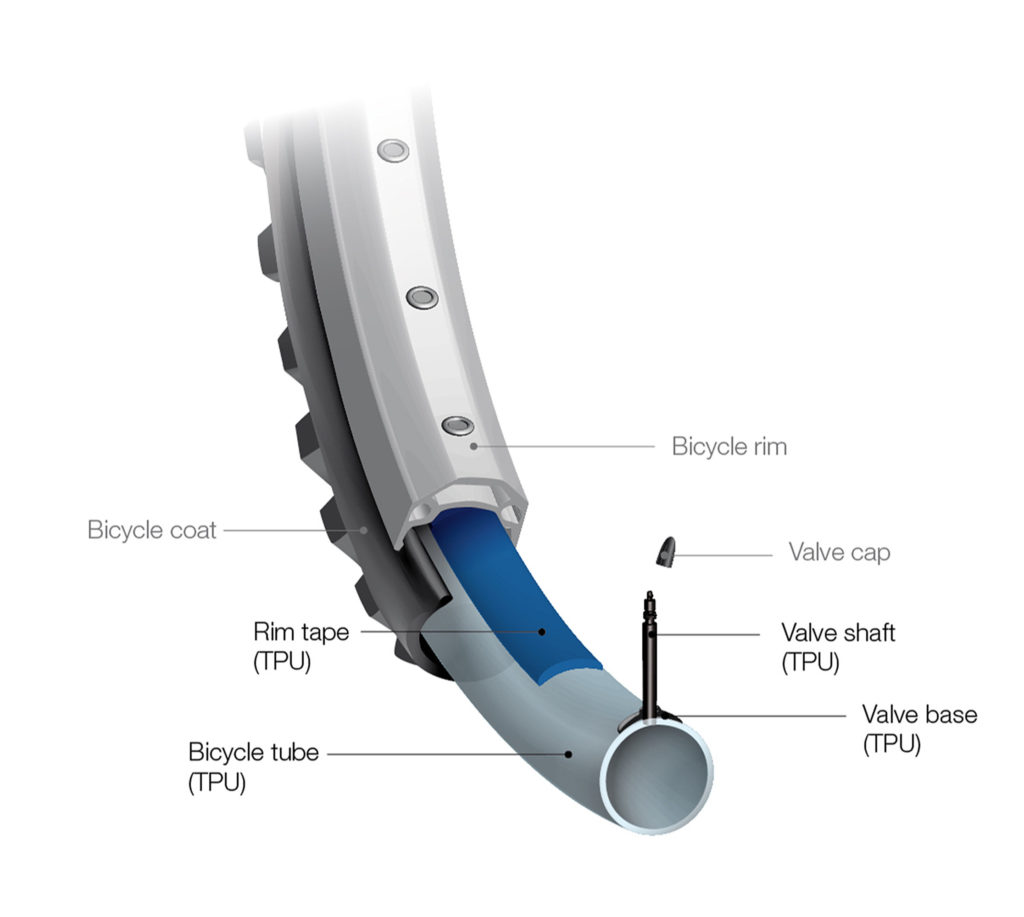

The Aerothan bicycle tubes are designed around a specially developed material combination based on BASF’s Elastollan. The close cooperation is characterised above all by the targeted material development and tube prototype production at BASF’s Lemförde Technical Center, followed by tube assembly and intensive testing at Schwalbe. As a result, an optimum mix of materials and processing has been achieved, such that the new bicycle tube not only offers good performance, but is also around 40 % lighter than the established alternatives on the market. To achieve this, all parts of the new tube, including the valve stem, are made entirely of Elastollan. The advantage of the reduced weight is not limited to just better handling, but is also evident in the smaller packing size, which makes the Aerothan tube an ideal backup tube, said the manufacturer.

Despite its low weight, the new tube offers cyclists a whole new level of puncture safety: the material prevents any sudden loss of air and ensures stable handling even at low tyre pressure. Aerothan bicycle tubes are therefore approved for all rim brakes and so are optimally suited to the high demands of racing bikes, mountain bikes or all-round cycling environments. Since Aerothan bicycle tubes can be changed quickly and easily without slipping or jamming, they are also easy to install in practice. This is enabled by the special mechanical properties of the TPU. Elastollan is highly resistant to abrasion and wear and is therefore very durable, even under sustained high pressure loads. At the same time, the material is very flexible, elastic and heat resistant.

“Elastollan allows the use of thin walls, in order to reduce weight and at the same time produce a bicycle tube that offers significant advantages over butyl- or rubber-based bicycle tubes both in terms of puncture resistance and handling and on the manufacturing side,” said Mark Ottens, Segment Manager Extrusion TPU at BASF.

Another advantage of the Aerothan bicycle tubes is their recyclability – they are made entirely of thermoplastic polyurethane. Like all Schwalbe tubes, Aerothan bicycle tubes can be returned to the manufacturer, easily and free of charge, via the tube recycling programme. The material of the old tubes is processed and then reused as sealing or insulating material.