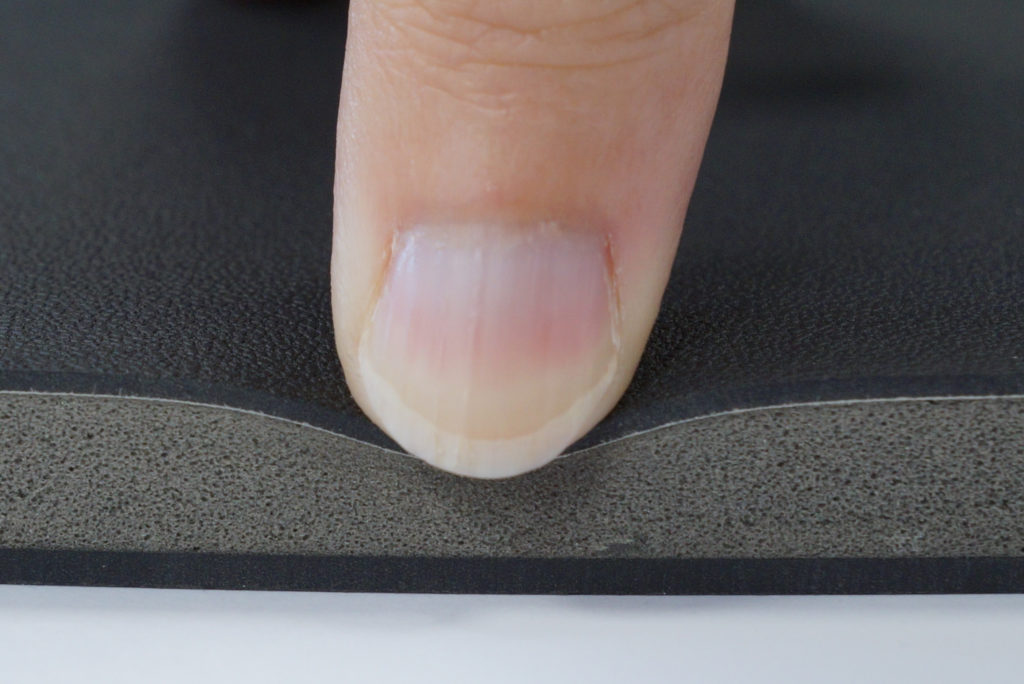

Dryflex HiF is a family of very high melt-flow and scratch resistant TPS-SEBS materials recently launched by Hexpol TPE. The grades open possibilities to produce large scale parts via injection moulding, including automotive interior surfaces, trims and skins.

Speaking of the development Dr. Thomas Köppl, group product manager Hexpol TPE commented; “There are several processing methods and materials on the market that allow production of automotive interior surfaces such as instrument panels and door trims. However, these processes can be costly, and the materials are not recyclable. OEMs are looking to improve their sustainability practices while also managing system costs. This is why we developed Dryflex HiF TPE.”

Dryflex HiF TPEs can be used in multi-component applications with direct overmoulding to polypropylene. Compared to existing TPU or PU-RIM processes, which often use PC/ABS as the rigid component, the material’s ability to adhere to PP can deliver further cost and weight reduction in 2K processes.

Dr. Köppl concluded: “In developing these materials we worked in close collaboration with Kraton Corporation, based on Kraton IMSS technology, Dryflex HiF TPEs deliver a combination of high-performance, soft-touch appeal, processing optimisation and recyclability. They are part of our growing portfolio of materials bringing new possibilities to the automotive industry”.