Marine oil spill barriers, also known as oil containment booms, can last longer and keep oil spills under control even under intense sunlight, thanks to light stabilisers from BASF. The South Korean company Wonpoong Corporation is now using BASF’s Tinuvin range of plastic additives to increase the lifespan of oil containment booms, thereby reducing the maintenance costs and environmental impact.

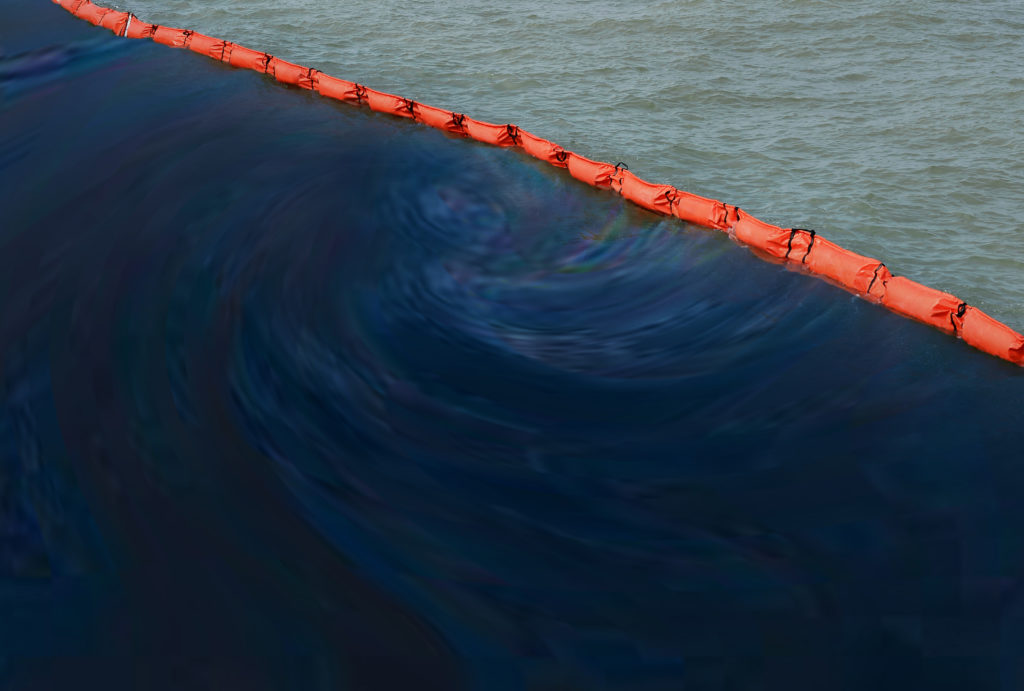

A containment boom is a heavy-duty debris and oil spill containment barrier, designed for a long service life with minimal maintenance. Made with marine grade components and oil-rated fabrics, these barriers can float in the water and contain oil while spill recovery is underway. This reduces the possibility of polluting shorelines and other resources, and to help make recovery easier.

The barrier fabric is usually made of woven polyester that is impregnated with polyurethane for better resistance to both abrasion and tear. The fabric is orange in colour, and requires protection from prolonged UV and hydrocarbon exposure which shortens the fabric life.

“Light stabilisers reduce and significantly delay the loss of optical and mechanical properties of plastic articles used in outdoor applications,” said Hermann Althoff, Senior Vice President, of BASF’s Performance Chemicals unit in Asia Pacific, BASF. “Our light stabilisers can increase the service life of the product several times, and simultaneously reduce the resource consumption caused by the aging of the product.”

Wonpoong chose a blend of PVC (polyvinyl chloride) and TPU (thermoplastic polyurethane) to manufacture the foam-filled oil containment booms. However, they do have some disadvantages. While TPU has better wear strength and softness compared to PVC, due to its poor resistance to light, TPU is easily discoloured.

“We needed to strengthen the chemical resistance of PVC while enhancing the light resistance of TPU,” said John Yu, Director of R&D at Wonpoong Corporation. “As a result, we required a light stabiliser with improved resistance to UV radiation that could preserve the original appearance and physical properties of the material.”

The choice was a light stabiliser package from BASF’s Tinuvin range, that is said to be ideal for PVC alloys like PVC/PU. This light stabiliser system is based on compounds of the sterically hindered amine light stabilisers (HALS). The hindered amines act in a similar manner to how vitamin C protects the human body; they intercept radicals and make them harmless. The duration of this protective effect can be controlled by selecting a specific stabiliser additive.