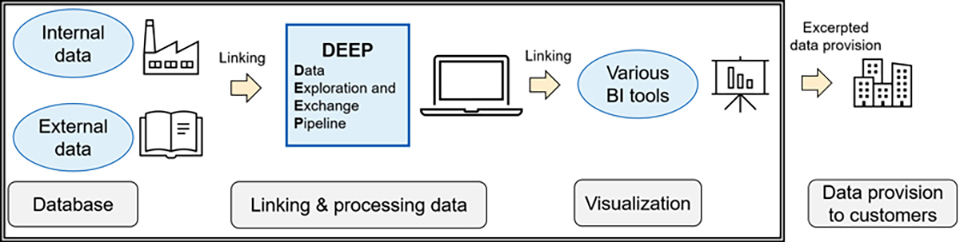

Asahi Kasei has developed a system (“System1”) to calculate the carbon footprint of products (CFP2) with CFP data provision to customers scheduled to begin in June 2022. CFP visualization is achieved utilizing the DEEP3 (Data Exploration and Exchange Pipeline) group-wide management infra-structure as a part of the System, which also enables examination of ways to further reduce CFP. The synthetic rubber and elastomers products include the brands Asadene, Tufdene, Asaprene, Tufprene, Asaflex, Tuftec, and S.O.E.

The Japanese group made efforts to strengthen the business platform for sustainable growth from the viewpoint of Green, Digital, and People in its previous medium-term management plan, Cs+ for Tomorrow 2021. In its new medium-term management plan, announced on 11 April 2022, Green Transformation is positioned as one of the key areas for strengthening the management foundation, and Asahi Kasei is advancing reductions of its own GHG emissions as well as contributions to reducing the world’s GHG emissions for the realization of carbon neutrality. Therefore, from the perspective of GHG emissions reduction, Asahi Kasei has sequentially advanced the calculation of CFP for each product starting with the main products, and information provision to certain customers has begun. As part of the effort to accelerate Green Transformation, Asahi Kasei has begun procuring butadiene derived from plastic waste and biomass as feedstock for S-SBR for eco-friendly tires (announcement from 24 November 2021).

For the CFP calculation by the System, the Life Cycle Inventory (LCI) database of “IDEAv2.3”, Inventory Database for Environmental Analysis, provided by Sustainable Management Promotion Organization (SuMPO), and the emissions intensity database provided by the Japanese Ministry of the Environment are used. Data sources are scheduled to be extended.

CFP is quantitatively calculated by combining the total GHG emissions from the entire life cycle of products and services, from raw material procurement to disposal and recycling, and then converting the figure into the equivalent amount of CO2. Asahi Kasei’s CFP calculation is based on “Cradle-to-Gate” assessment, which combines upstream emissions of materials and transportation, emissions from in-house manufacturing processes, and energy-related emissions such as electricity used during manufacturing.