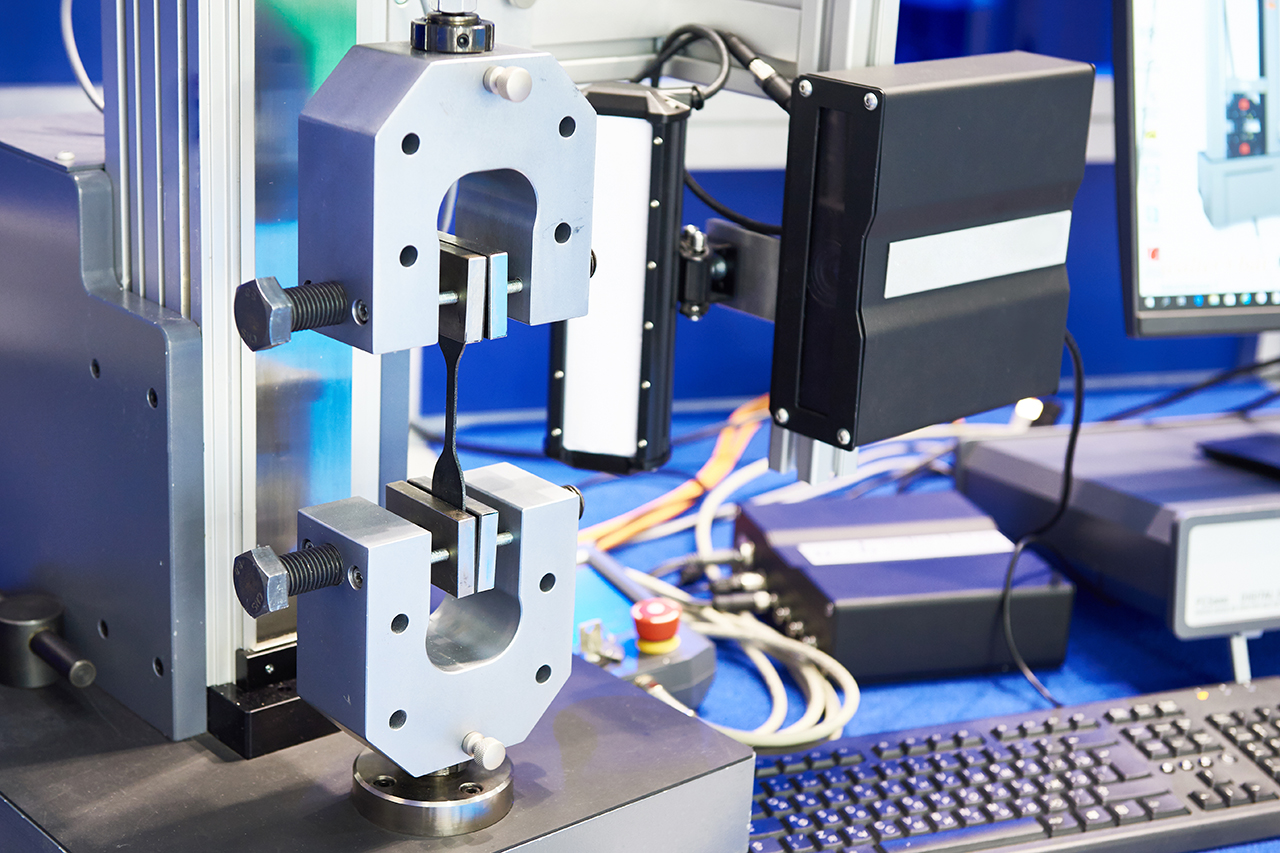

APS Elastomers has set up a new state-of-the-art lab after moving to a larger facility in Westland, Michigan, USA, in 2020. With the new laboratory APS can provide in-depth and high- level customer and technical service, problem-solving, product development and support to designers, OEMs and processors. Capabilities including tensile strength, melt flow rate, density, durometer hardness, melting point, gel count, stress at 100% and 300%, elongation at break, tear strength, and taber abrasion loss.

“Our new lab allows us to test and compare materials to find what is best suited for our customer’s needs”, says Roger Huarng, co-owner of APS Elastomers.

In addition to full laboratory services, the recent purchase of BT25 Pelletizer enables APS to blend small proprietary batches for fast turnaround time; assisting their customers with a broad range of custom blends, including color concentrates that are FDA, RoHS, CONEG, and NSF compliant and heavy-metal free.