The speciality vibration damping Versaflex VDT TPEs from PolyOne are used by major appliance manufacturers as a valuable solution to vibration issues in top load washing machines which can cause the units to ‘walk,’ which prompts a large volume of costly service calls to the manufacturer.

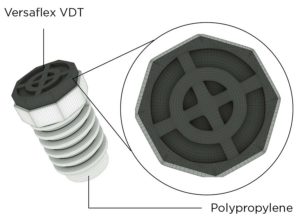

The company says that when using Versaflex VDT, kinetic energy generated by the washing machine movement activates molecules in the material, which then converts the kinetic energy into heat energy, reducing vibration and ‘walking.’ In addition, the material is said to withstand wear and tear of daily use, can be overmoulded easily onto polypropylene, and reduces cycle time through the elimination of secondary operations, such as drying. PolyOne says that although TPV and EPDM have historically been used in this application, they are less effective in minimising appliance ‘walking’ and require longer production cycle times.

“Recently, we applied our material and design expertise to help a major appliance manufacturer reduce vibration on their latest top load washing machine model. In an experiment completed by this customers’ design team, switching to Versaflex VDT TPE reduced vibration of the appliance by 80 percent versus TPV,” said Michelle Hearn, global marketing director, Specialty Engineered Materials at PolyOne.

| To help customers learn more about using Versaflex VDT TPE materials to mitigate vibration, PolyOne recently published the Smart Materials Vibration and Sound eBook. |