Virginia Tech researchers have discovered a novel process to 3D print latex rubber, unlocking the ability to print a variety of elastic materials with complex geometric shapes. 3D printed latex has been documented only a handful of times in scientific literature. None of the previous examples come close to the mechanical properties of the latex printed by an interdisciplinary team affiliated with the Macromolecules Innovation Institute (MII), the College of Science, and the College of Engineering.

Through innovations in both the chemistry and mechanical engineering disciplines, a team of scientists from Macromolecules Innovation Institute (MII), the College of Science, and the College of Engineering at Virginia Tech overcame some long-standing limitations of 3D printing, also known as additive manufacturing. The researchers chemically modified liquid latexes to make them printable and built a custom 3D printer with an embedded computer vision system to print accurate, high-resolution features of this high-performance material.

„This project represents the quintessential example of interdisciplinary research,“ said Timothy Long, a professor of chemistry and a co-principal investigator on this project along with Christopher Williams, the L.S. Randolph Professor of mechanical engineering and interim director of MII. „Neither of our labs would be able to accomplish this without the other.“

This project is a joint collaboration between Virginia Tech and Michelin North America via a National Science Foundation award aligned with the Grant Opportunities for Academic Liaison with Industry program, which supports teamed research between academia and industry. Details of their initial results are detailed in a journal article published in ACS Applied Materials & Interfaces [1].

Usually, high molecular weight polymers are not amenable to vat photopolymerization (VP) additive manufacturing due to high solution and melt viscosities. Phil Scott, a fifth-year macromolecular science and engineering student in the Long Research Group, turned to commercial liquid latexes as a way of decoupling the dependency of viscosity on molecular weight. The chemists came up with the idea of building a scaffold, similar to those used in building construction, around the latex particles to hold them in place. The scaffold is built up of 1-vinylpyrrolidone (NVP) and poly(ethylene glycol)diacrylate (PEGDA) monomers which are photo-cured in the continuous phase of SBR latex to yield a hydrogel embedded with SBR particles.

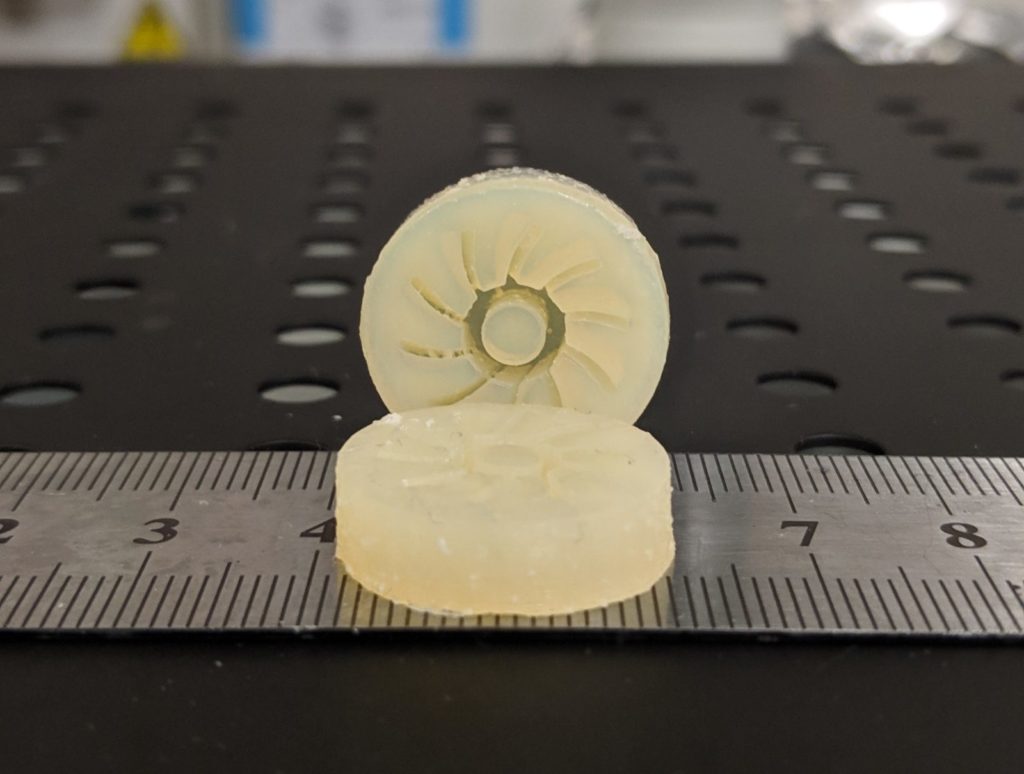

The printing process was vat photopolymerization, in which the printer uses UV light to cure, or harden, a viscous resin into a specific shape. For this a printer capable of printing high-resolution features across a large area was needed, which was built by Viswanath Meenakshisundaram, a fifth-year mechanical engineering Ph.D. student in the Design, Research, and Education for Additive Manufacturing Systems Lab. He and Williams, his advisor, came up with the idea to scan the UV light across a large area, and in 2017, they filed a patent for the printer.

Even with the custom printer, the fluid latex particles caused scattering outside of the projected UV light on the latex resin surface, which resulted in printing inaccurate parts. So Meenakshisundaram embedded a camera onto the printer to capture an image of each vat of latex resin. With his custom algorithm, the machine is able to „see“ the UV light’s interaction on the resin surface and then automatically adjust the printing parameters to correct for the resin scattering to cure just the intended shape. Meenakshisundaram and Scott discovered their final 3D printed latex parts exhibited strong mechanical properties in a matrix known as a semi-interpenetrating polymer network, which hadn’t been documented for elastomeric latexes in the prior literature.

The novel advances in both materials development and processing highlight the interdisciplinary environment fostered between the two groups. Long and Williams both credited their counterpart’s expertise for making the collective breakthrough possible. The two professors said 3-D printed latex provides the conceptual framework for printing a range of unprecedented materials from rigid plastics to soft rubbers, which have been unprintable until now.

[1] P. J. Scott, V. Meenakshisundaram, M. Hegde, C. R. Kasprzak, C. R. Winkler, K. D. Feller, C. B. Williams, T. E. Long, 3D Printing Latex: A Route to Complex Geometries of High Molecular Weight Polymers, ACS Applied Materials & Interfaces 2020 12 (9), 10918-10928.